Interactive Air Loop

Click on the steps in our air cleaning process to learn more.

Pre Filter

A prefilter is often used as an investment to protect the more expensive secondary filter.

Secondary Filter

This filter is generally the final filter that the air sees before it goes to the conditioned space.

Cooling Coil

The cooling coil is the heart of the Fan Coil Unit. This is where the heat transfer happens. If coils are not maintained to near new condition, the unit will use excessive amounts of energy. If left unmanaged, they can become breeding grounds for mold, mildew, bacteria, and other types of growth that can cause human diseases.

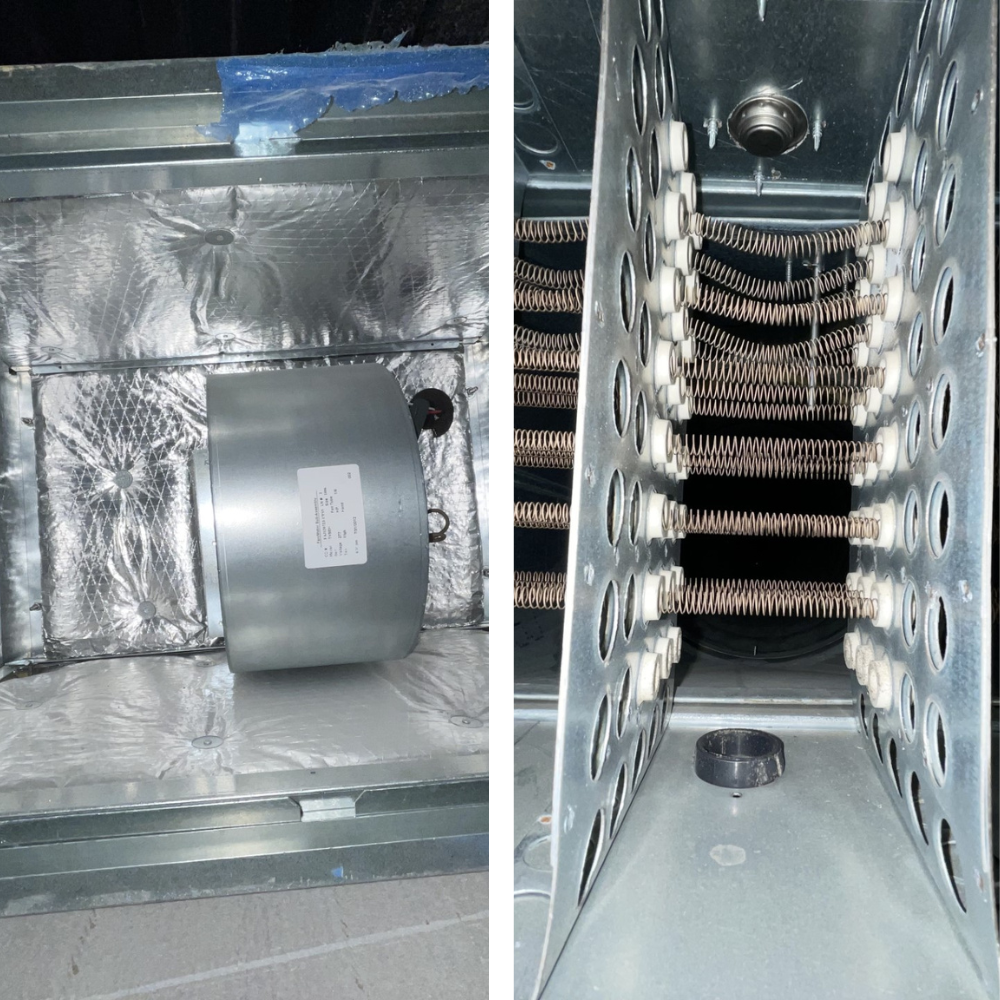

Heating Coil

The fins on a heating coil are typically spaced further apart than the cooling coil fins and the coil is usually not as deep. Because of this, they typically do not foul nearly as quickly as cooling coils, but they do need to be cleaned if visibly contaminated.

Drain Pan

The drain pan is often a major source of biological growth. These pans need to be kept as clean as possible. A common problem is that the contaminants in the drain pan will clog the drain line potentially causing the entire base of the unit to get wet. This can easily and quickly evolve into a mold problem.

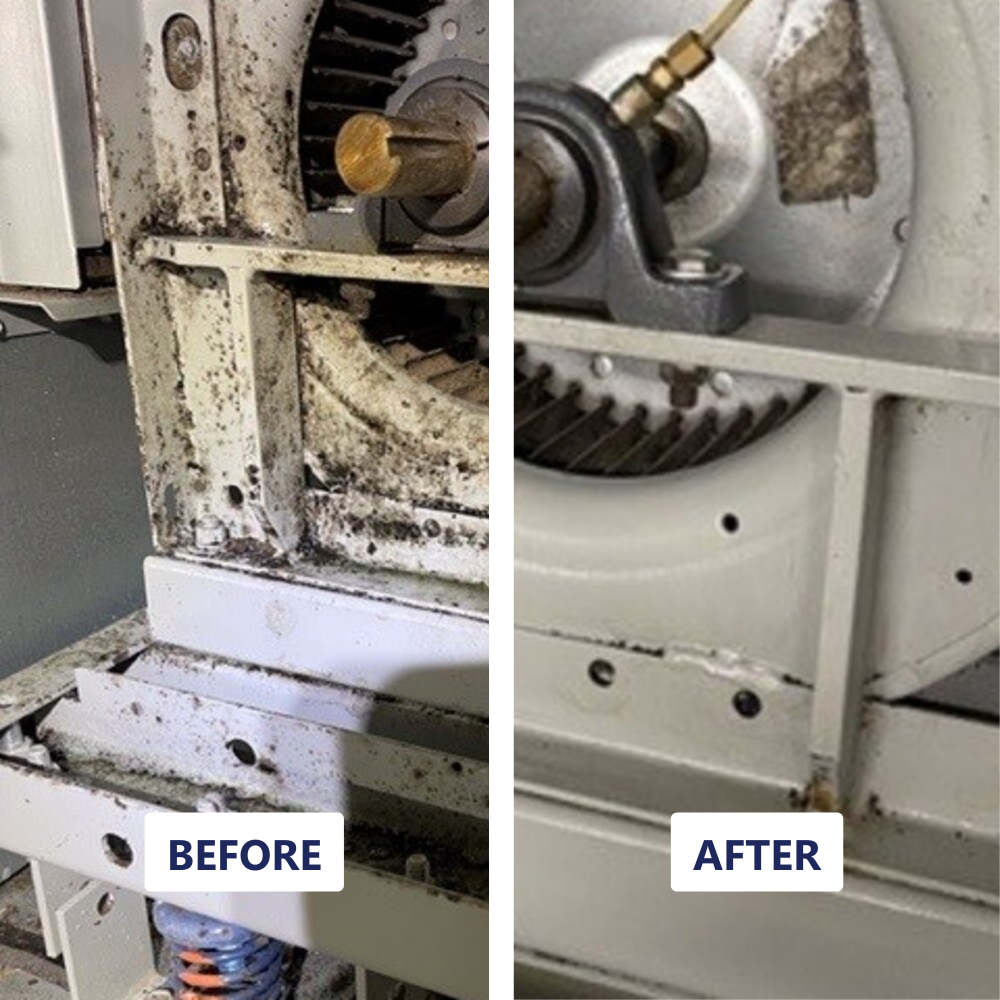

Supply Fan

The supply fan is the primary driver of the air through the air loop. Even a small buildup on these fan blades can cause excessive energy waste.

Final Filter

The phrase “final filter” typically dictates that this is the last filter that the air will encounter before being introduced to the occupied space. These can often be very restrictive to airflow even when they are new.

Turning Vane

The turning vane’s purpose is to reduce air friction as the air tries to change directions inside the turn in a duct system. Since they are located within the path of the air, they normally get dirty relatively quickly. If the turning vanes are not kept clean, they can waste a lot of energy.

Supply Duct

Even though the air traveling through a supply duct may have been filtered, these ducts still get dirty. The main concern for dirty supply ducts is that anything that breaks free inside of them goes straight to the occupied space. Some people suggest that if the dirt has settled in the supply duct does it makes sense just to leave it there. We disagree. Duct work gets shaken and/or vibrated for various mechanical reasons. This allows contaminants to break free allowing them to go downstream unobstructed. Another major concern of having dirty supply ducts is if there is a high moisture event in the duct system, the contaminants inside of the supply ducts can quickly develop into a mold problem.

Return Grill

This is where the air in the occupied space is returned to the air conditioning unit. These very often build up a lot of restrictions due to the dirt from the occupied space clogging in them. When this happens, the unit must work much harder to maintain airflow, thus using more energy.

Return Duct

Return ducts return air from the occupied space to the unit and is typically unfiltered. This unfiltered air can quickly contaminate and build up in return ducts. Typically return ducts foul more quickly than supply ducts, thus they need to be cleaned more often.

Exhaust Grill

These components are often very similar to the ones used within the air conditioning system. However, since they are rarely filtered, this is often the first problematic area for ducts becoming contaminated.

Exhaust Duct

These components are often very similar to the ones used within the air conditioning system. However, since they are rarely filtered, this is often the first problematic area for ducts becoming contaminated.

Exhaust Fan

These components are often very similar to the ones used within the air conditioning system. However, since they are rarely filtered, this is often the first problematic area for ducts becoming contaminated.

VAV Box

Variable air volume boxes are installed to allow for the adjustment of air volume to the duct they feed. These are often one of the first places dirt starts to become a problem within an air conditioning system.

How Can

We Help?

Our nationally certified team of Filtration Experts is ready to help. Please complete and submit the contact form and a Carolina Filter Supply representative will contact you.

|

For over 50 years, Carolina Filters, Inc. has supported mission-critical filtration applications with specialized cleaning and testing processes. Our engineered solutions solve complex challenges for customers across a broad spectrum of markets. Explore our family of filtration solutions: • For Process Equipment Cleaning Solutions, visit Carolina PEC. • For Indoor Air Quality Solutions, visit Carolina IAQ. • For Air and Liquid Filtration Solutions, stay on Carolina Filter Supply. |

|

Stay in Touch.

Sign up for the latest updates from Carolina Filter Supply.

© 2025 Carolina Filters, Inc. All Rights Reserved|

Privacy Policy | Cookie Policy |

Site by ALINE, A Marketing Company

VAV Box

VAV Box